MILOO ELECTRONICS Sp. z o. o. invites you to take advantage of the offer of comprehensive services in the field of processing various types of metal materials.

Thanks to a modern machine park equipped with innovative devices and an experienced team of specialists, we offer a wide range of executive services:

LASER CUTTING - currently the fastest and most accurate method of metalworking using the SALVAGNINI L3 laser:

- Maximum working area - 3000 x 1500 mm;

- Range of processed materials:

| Black steel | 0,5 – 20 mm |

| Stainless steel | 0,5 – 12 mm |

| Aluminium | 0,3 – 10 mm |

| Brass | 0,5 – 6 mm |

| Cooper | 0,5 – 8 mm |

BENDING - using the modern, electric SALVAGNINI P1 bending center, which allows faster and more accurate sheet bending:

- Range of sheet thickness bent: 0.3 - 1.5 mm;

- Maximum bending edge length: 1250 mm

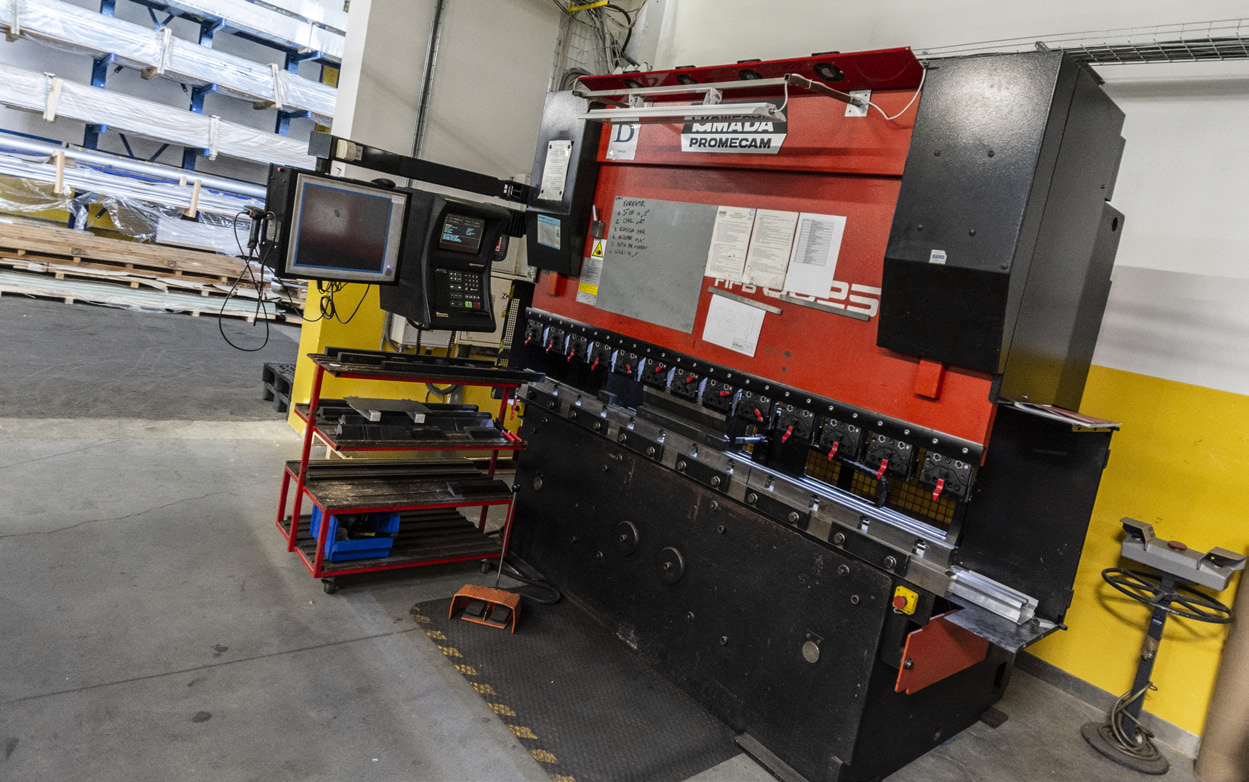

80T BENDING PRESS:

- Range of bent sheet thickness: 0.3 - 6.0 mm;

- Maximum bending edge length: 2500 mm.

WIG MIG / MAG WELDING - thanks to modern equipment and employees with many years of experience we can

CUTTING ALUMINUM AND PLASTICS:

- Circular saw blades with one and two heads with cutting options for both single and serial;

- The ability to cut angles in the range of 0 - 135 degrees;

- Cutting with an accuracy of 0.1 mm;

- Length of maximum cut elements 4000 mm;

CNC TURNING AND MILLING

- Maximum work area:

- Milling Center 2000 x 1000 x 1000 mm;;

- Turning Center fi300 x 450 mm;

- We process materials such as Aluminum, Steel, Stainless Steel, Brass, Copper, Plastics;

- We make forms, single and serial elements

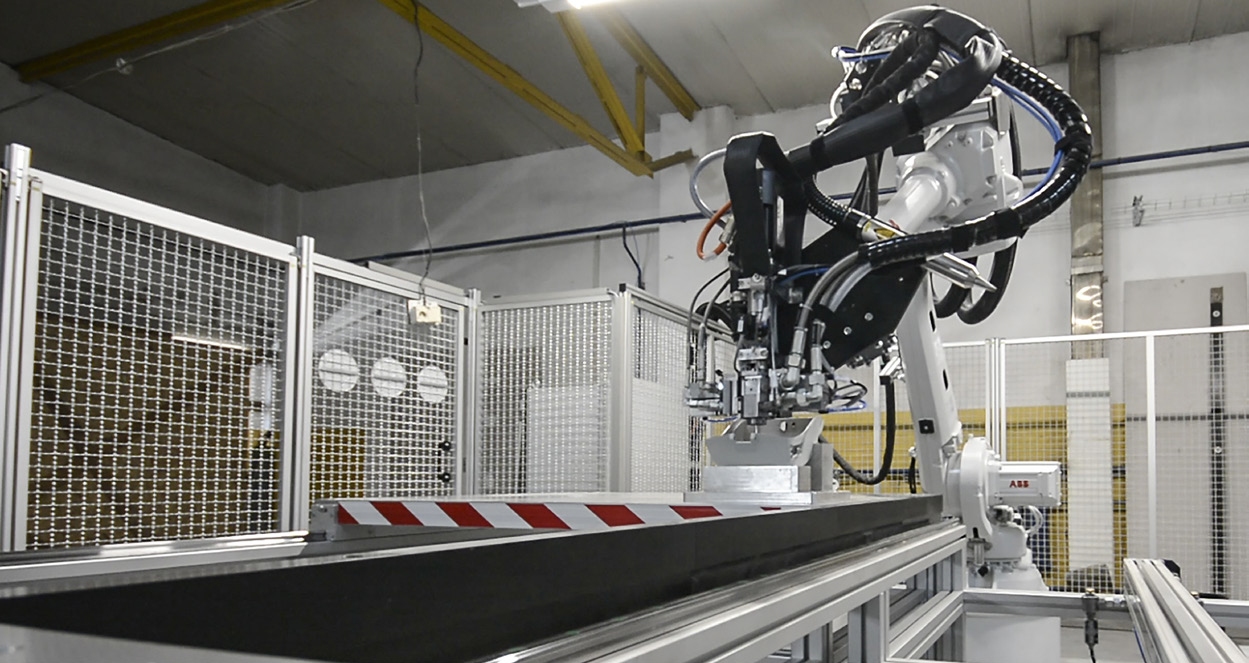

PURING POLYURETHANE SEALS - using the SONDERHOFF system

- PURING POLYURETHANE SEALS - using the SONDERHOFF system

- The ability to adjust the width and height of the gaskets to customer needs;

- Obtaining tightness after compressing the seal.

We invite you to cooperation.